Table of Contents

ToggleIntroduction

In recent years, WPC composite decking has become one of the most popular outdoor flooring materials worldwide. From residential gardens and swimming pool surrounds to large commercial projects such as hotels, resorts, and public walkways, composite decking is rapidly replacing traditional wood due to its durability, stability, and low maintenance. For importers, wholesalers, builders, and architects, understanding what WPC composite decking is—and why it has become a preferred solution—is essential for making better procurement and project decisions.

This article provides a comprehensive explanation of WPC composite decking, including its definition, raw materials, production technologies, key advantages, application fields, installation considerations, and global market trends. As a professional WPC decking manufacturer and exporter from China, we will also explain why Chinese suppliers play a major role in the global composite materials industry.

What Is WPC Composite Decking?

WPC stands for Wood-Plastic Composite, a new type of eco-friendly material created by combining wood fiber and thermoplastics through advanced extrusion technology. Unlike pure wood, which is prone to cracking, warping, and decay, WPC decking provides enhanced durability and stability while maintaining the natural beauty of wood.

1.1 Basic Definition

WPC composite decking is a structural decking material made from:

- Wood fiber / wood flour

- Recycled plastics (PE is most commonly used)

- Additives (stabilizers, colorants, lubricants, antioxidants, UV inhibitors)

These raw materials are mixed under high temperature and pressure and formed into decking boards with various colors, textures, and finishes.

1.2 Why It’s Called “Composite”

The term “composite” refers to its hybrid structure—wood components provide a natural look and mechanical strength, while plastic components provide waterproofing, weather resistance, and extended lifespan.

1.3 Eco-Friendly Nature

WPC decking is considered an environmentally friendly alternative to timber because:

- It uses recycled plastic, reducing environmental waste.

- It reduces the demand for natural wood, helping protect forests.

- It has a longer life cycle, reducing replacement waste.

Raw Materials and Manufacturing Process of WPC Decking

Understanding how WPC decking is made helps buyers evaluate quality and select reliable suppliers.

2.1 Raw Materials Composition

A typical WPC decking formula includes:

| Material | Percentage | Function |

|---|---|---|

| Wood fiber | 50–65% | Strength, rigidity, natural appearance |

| Recycled PE plastic | 25–35% | Waterproofing, impact resistance |

| Additives | 5–15% | UV protection, coloring, fire retardant, mold resistance |

Higher-quality decking typically uses high-density polyethylene (HDPE) for better hardness and structural stability.

2.2 WPC Decking Production Process

Step 1: Raw Material Mixing

Wood fiber is dried to reduce moisture and mixed with plastic granules and additives.

Step 2: Extrusion Molding

The mixture is fed into an extrusion machine that shapes the molten material into decking profiles.

Step 3: Cooling and Cutting

The extruded boards pass through a cooling tank and are cut to standard or custom lengths.

Step 4: Surface Treatment

Depending on the product type, the surface may undergo:

- Sanding

- Brushing

- Wood-grain embossing

- Co-extrusion capping

Step 5: Quality Inspection & Packaging

Boards are inspected for color consistency, thickness, hardness, and density before packaging.

Key Advantages of WPC Composite Decking

WPC decking’s global popularity is driven by its strong performance.

3.1 Waterproof and Moisture-Proof

Unlike wood, WPC does not absorb water, preventing:

- Rot

- Swelling

- Mold growth

It is ideal for humid or rainy climates.

3.2 High Durability

WPC decking is resistant to:

- UV radiation

- Insects and termites

- Cracking and splintering

- High/low temperature changes

It can last 15–25 years, depending on quality.

3.3 Low Maintenance

No painting, sealing, or oiling is required. Cleaning only needs:

- Soap

- Water

- A soft brush

This saves long-term maintenance costs.

3.4 Slip Resistance

The textured surface provides good traction even when wet, making it suitable for:

- Pools

- Marinas

- Hotels

- Public walkways

3.5 Eco-Friendly

WPC is recyclable and sustainable, offering a green alternative to traditional wood.

3.6 Better Color Stability

UV inhibitors in the formula help prevent color fading. Co-extruded decking provides even stronger color stability.

Main Types and Surface Options of WPC Decking

Different markets and applications require different decking types. The three main categories include:

4.1 Traditional WPC Decking

- One-layer structure

- Embossed or brushed surface

- Low cost

- Suitable for budget-oriented projects

4.2 Co-Extrusion “Capped” WPC Decking

Co-extrusion decking adds an extra plastic protective layer on the outside.

Benefits:

- Superior UV resistance

- No cracking

- Excellent stain resistance

- Bright and long-lasting colors

This type is ideal for high-end residential or commercial projects.

4.3 3D Wood-Grain Decking

3D embossing gives a deeper, more realistic wood texture. Popular in markets like:

- Europe

- USA

- Australia

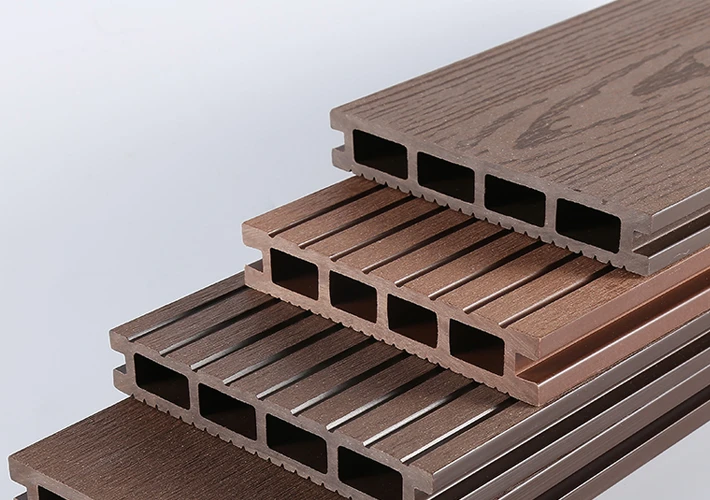

4.4 Hollow vs Solid Decking

Hollow Decking

- Lightweight

- Cost-effective

- Suitable for residential use

Solid Decking

- Stronger load-bearing

- Suitable for public areas and heavy-duty applications

Applications of WPC Decking in Residential & Commercial Projects

WPC decking is highly versatile and used in various outdoor environments.

5.1 Residential Applications

- Backyard decks

- Balconies

- Garden paths

- Swimming pool sides

- Patio flooring

5.2 Commercial Applications

- Resorts and hotels

- Outdoor restaurants

- Shopping malls

- Public boardwalks

- Sports venues

- Schools and parks

Because of its stability and low maintenance, it is favored by construction contractors and landscape designers.

Why Import WPC Composite Decking from China?

China is the world’s largest WPC decking production base, supplying more than 70% of global demand. Choosing a Chinese manufacturer provides major benefits:

6.1 Competitive Pricing

Lower labor and production costs allow China to offer the best cost-performance ratio.

6.2 Mature Production Technology

China has more than 15 years of WPC manufacturing expertise, with:

- Fully automated extrusion lines

- Co-extrusion technology

- Precise color control

- Strict quality inspection systems

6.3 Wide Range of Product Options

Factories offer:

- Solid & hollow profiles

- 3D wood grain designs

- Co-extrusion capped decking

- Accessories including clips, joists, skirting

6.4 Strong Supply Chain Capacity

Fast production and delivery from major manufacturing hubs like:

- Zhejiang

- Anhui

- Jiangsu

- Guangdong

6.5 OEM & Branding Services

Chinese suppliers can support:

- Logo printing

- Custom packaging

- Customized colors

- Exclusive mold development

Perfect for distributors and brand owners.

Conclusion

WPC composite decking is an advanced outdoor flooring material that combines the natural beauty of wood with the superior durability of plastic. Its waterproof performance, long service life, low maintenance requirements, slip resistance, and environmental benefits make it ideal for both residential and commercial applications.

For global buyers, choosing the right manufacturer directly affects product quality, market competitiveness, and project satisfaction. As a professional WPC decking manufacturer & China supplier, we offer high-quality co-extrusion decking, traditional WPC decking, composite cladding, fencing, and complete installation accessories to support wholesalers, distributors, and project contractors.

If you need help choosing decking types, requesting catalogs, samples, or pricing, feel free to contact us anytime.