Composite cladding has become one of the fastest-growing categories in the global building materials industry. With the rapid rise of modular buildings, hotel renovations, prefabricated housing, and sustainable construction, the need for safer, stronger, and easier-to-install façade systems continues increasing.

Among all modern exterior cladding installation systems, the Composite Cladding Lock 7 System is now considered one of the most advanced structural designs. From its seven-point locking mechanism to its impressive weather performance, it has become the preferred cladding solution for developers, wholesalers, architects, and installers in more than 60 countries.

Table of Contents

ToggleWhat Exactly Is the Composite Cladding Lock 7 System?

The Composite Cladding Lock 7 System refers to a unique seven-function interlocking mechanism engineered specifically for WPC (Wood Plastic Composite) and co-extruded façade panels. This system ensures each composite cladding board mechanically locks into the next through multiple points, improving stability, waterproofing, and long-term durability.

The Lock 7 system is designed to solve common cladding problems:

- Loose panels due to temperature changes

- Water seepage behind cladding

- Visible gaps after installation

- Warping or buckling under extreme weather

- Uneven alignment on large building façades

To achieve these improvements, the system integrates multiple mechanical and structural features:

Seven Locking Functions of the Lock 7 System

Primary Interlock: The main horizontal lock ensures strong engagement between boards.

Anti-Slip Structure: Prevents downward sliding over time.

Compression Fit: Tight vertical pressure sealing for better airtightness.

Wind-Resistant Groove: Extra hold against strong winds.

Thermal Expansion Buffer: Allows safe expansion without deformation.

Alignment Rail: Keeps long boards perfectly straight.

Drainage Channel: Guides water flow to avoid wall moisture issues.

These seven features work together to create a heavy-duty, long-lasting cladding façade that can withstand extreme climates, from snowy Canada to tropical Southeast Asia.

Why the Lock 7 System Became Popular Worldwide

- Modern buildings require stronger mechanical performance.

- Global weather is becoming more unpredictable, increasing the need for durable façades.

- Construction labor costs are rising — Lock 7 reduces installation time.

- Architects prefer seamless, screw-free, modern exterior façades.

- Developers demand lower long-term maintenance costs.

As a result, the Lock 7 system has become the standard for premium composite cladding in high-end residential, hospitality, commercial, and industrial buildings.

Structural Design & Working Mechanism of the Lock 7 System

Understanding the internal mechanics behind Lock 7 helps buyers evaluate quality, compare suppliers, and optimize installation efficiency.

2.1 Multi-Point Mechanical Locking System

Unlike conventional tongue-and-groove or simple clip systems, Lock 7 uses multiple interlocking geometries that increase board-to-board contact area.

Engineering advantages:

- Higher structural stability

- Long-term deformation resistance

- Better load distribution

- Minimal vibration and movement

- Zero visible gaps

This is especially important for:

- High-rise buildings

- Large exterior façades

- Coastal areas with high winds

- Hot-cold alternating climates

2.2 Co-Extrusion Surface Technology

Most Lock 7 products are manufactured through CE (co-extrusion) technology, where a protective layer is fused to the surface.

Benefits of co-extrusion:

- Superior UV resistance (5000–8000 hours test)

- 10+ years color stability

- No fading or chalking

- High scratch resistance

- Excellent stain resistance

- Anti-mold performance

- Improved waterproofing

Factories typically use premium additives such as:

- Clariant colorants (Germany)

- BASF anti-UV agents

- Dupont coupling agents

This ensures consistent quality for export markets.

2.3 Hidden-Screw Installation System

The Lock 7 design includes a concealed mounting channel, allowing installers to use screws without exposing them on the façade surface.

Benefits:

- Sleek, modern, clean look

- Better waterproof performance

- No risk of screws rusting in coastal areas

- No thermal bridge issues

- Reduced maintenance

Hidden-screw systems are preferred by architects designing:

- Luxury villas

- Five-star hotels

- Corporate HQ buildings

- Modern resort projects

2.4 Ventilated Façade (Rain Screen Principle)

The Lock 7 system naturally creates a small air gap behind the panels.

This allows:

- Moisture ventilation

- Temperature balancing

- Prevention of mold and condensation

- Enhanced wall insulation

This rain-screen design is widely used in Europe and complies with:

- EN 13501 fire testing standards

- CE building façade guidelines

2.5 Thermal Expansion Management

Composite materials expand slightly at higher temperatures. Poorly designed cladding may crack, bulge, or warp.

The Lock 7 system includes:

- Expansion grooves

- Compression seals

- Floating installation points

This reduces deformation and ensures safe installation in:

- Hot climates (Middle East)

- Cold regions (North America)

- Areas with big day-night temperature differences

Main Advantages of the Composite Cladding Lock 7 System

Below is a deeper analysis of the advantages from the perspective of engineering, installation, maintenance, and long-term performance.

3.1 Superior Mechanical Stability

The seven-lock structure creates a rigid façade system capable of handling:

- Strong winds

- Heavy rain

- Thermal stress

- Impact from debris

Compared with older systems, Lock 7 provides up to 40% higher structural stability.

3.2 Outstanding Waterproofing & Moisture Resistance

The compression-fit locks and drainage channels prevent:

- Wall seepage

- Insulation damage

- Mold growth

- Freeze–thaw wall cracking

In rainy areas like the UK, Ireland, Germany, and Japan, this is a critical advantage.

3.3 30–50% Faster Installation

Because boards automatically “click” into place, installation becomes:

- Faster

- Easier

- More consistent

- Less dependent on experienced workers

Labor cost savings are significant for:

- Large villa projects

- Hotel façades

- Multi-building developments

- Prefabricated housing factories

3.4 Enhanced Wind Load Performance

The Lock 7 system withstands wind speeds of up to 40–50 m/s, making it suitable for:

- Coastal buildings

- High-rise apartments

- Island resorts

- Mountain regions

Many local authorities require strong wind-load compliance, and Lock 7 meets those standards easily.

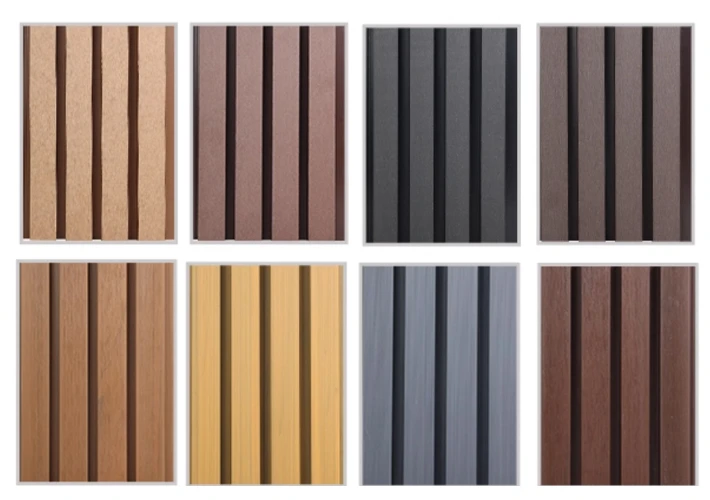

3.5 Long-Term Aesthetic Performance

The co-extruded surface ensures:

- Natural, deep 3D wood texture

- Fade resistance for 10–15 years

- No surface chalking

- High stain resistance (food, oil, dust)

- High scratch resistance

For homeowners and hotels, long-term appearance performance is a key value point.

3.6 Low Maintenance Over Life Cycle

Lock 7 cladding requires:

- No painting

- No oiling

- No sanding

- No termite treatment

- Only simple water cleaning

Compared with wood, it reduces lifetime maintenance costs by 70–90%.

3.7 Fire Resistance Options

Many Chinese factories provide FR-rated Lock 7 cladding:

- Class B1 fire rating (GB Standard)

- EN 13501 B-s2,d0 rating (EU)

This makes it suitable for:

- High-traffic commercial projects

- Apartment building façades

- Public buildings

- Hotels & resorts

Applications & Use Scenarios of Lock 7 Composite Cladding

The versatility of the Lock 7 system makes it ideal for dozens of architectural environments.

4.1 Residential Applications

Used widely in:

- Luxury villa façades

- Garden houses

- Prefab homes

- Container homes

- Balconies & exterior corridors

Reasons homeowners prefer Lock 7:

- Fast installation

- Stunning appearance

- Zero maintenance burden

4.2 Hotel & Hospitality Projects

Hotels demand elegant, stable, and weather-resistant façades. Lock 7 is used in:

- Resorts

- Seaside hotels

- Mountain lodges

- Boutique inns

- Serviced apartments

Benefits for hotel developers:

- Modern textured wood appearance

- Ability to withstand moisture & salt air

- Long-term color stability

- Suitable for large-scale façade coverage

4.3 Commercial & Public Buildings

Composite cladding with Lock 7 is ideal for:

- Corporate office buildings

- Shopping malls

- Car showrooms

- Government buildings

- Educational institutions

These projects require:

- Strong durability

- Modern design

- Consistent color across large areas

- Good fire performance

4.4 Industrial & Warehouse Buildings

Factories and logistics centers benefit from:

- Low-cost large-area coverage

- Strong weather resistance

- Zero maintenance

- Fast project completion timeline

Lock 7 cladding outperforms metal sheets in insulation, aesthetics, and noise reduction.

4.5 Renovation / Re-Cladding Projects

Because the Lock 7 system is lightweight and easy to install over existing surfaces, it is ideal for:

- Old building façade upgrades

- Outdated tiled-wall replacement

- Damaged wooden façade replacement

- Insulation retrofits

It helps developers modernize projects without costly structural renovation.

Technical Specifications, Standards, Installation & Market Demand

This section includes detailed specifications and standards required by global B2B buyers.

5.1 Common Composite Cladding Sizes

- Thickness: 20 mm / 21 mm / 22 mm / 26 mm

- Width: 140 mm / 157 mm / 170 mm / 200 mm

- Length: 2.2 m / 2.9 m / 3.6 m / 4 m / custom

- Surface: 3D grain, brushed, matte co-extrusion

- Fire rating: Optional B1 / B-s2,d0

5.2 Material Composition (Professional Breakdown)

Typical WPC Lock 7 material formula:

- 55–60% wood fiber

- 30–35% HDPE

- 5–10% additives (anti-UV, stabilizers, colorants)

Co-extruded surface typically includes:

- HDPE capping

- UV-resistant agents

- Color stabilizers

- Anti-scratch materials

5.3 Installation Steps (Detailed Version)

Install joists (spacing 400–500 mm).

Add starter clips at the bottom.

Insert first cladding board.

Lock the next board into the seven-point channel.

Secure using hidden screws.

Install L / U / T trims at edges and corners.

Perform expansion-check spacing.

Final quality alignment check.

The entire process is simple enough that 1–2 workers can complete a house façade installation in 2–3 days, depending on size.

5.4 Global Market Growth

Demand for composite cladding, especially Lock 7 system, is rapidly increasing.

Fast-growing regions:

- Australia

- UK & Ireland

- Germany & Netherlands

- Saudi Arabia & UAE

- Canada & USA

- New Zealand

Growth drivers:

- More prefabricated houses

- Stricter construction standards

- Higher labor, making fast-install systems essential

- Shift from wood to composite materials

- Sustainability & low-maintenance demand

Why Import Lock 7 Composite Cladding from China?

As a professional composite cladding manufacturer in China, we supply high-quality, export-grade Lock 7 systems to global wholesalers, brands, contractors, hotel developers, and distributors.

Below is an expanded explanation of why China is the best source.

6.1 Factory-Direct Pricing Saves 20–40%

Chinese WPC factories operate large-scale automated lines:

- 24 extrusion lines

- Daily production 60–90 tons

- Bulk raw material sourcing

- Lower labor and operational cost

This ensures lower prices without sacrificing quality.

6.2 Advanced Production Technology

We use:

- Imported German twin-screw extruders

- Automated batching systems

- Co-extrusion ultrasonic calibration

- High-precision mold tooling

This guarantees:

- Consistent thickness tolerance

- High-strength locking mechanism

- Color consistency across batches

6.3 Strict Quality Assurance

Each batch of Lock 7 cladding undergoes:

- UV aging testing

- Water absorption test

- Mechanical tensile testing

- Color difference inspection

- Wind load testing

- Fire rating certification

Only qualified materials are shipped.

6.4 OEM & Private-Label Support for B2B Buyers

We offer:

- Custom color development

- Customized wood grain textures

- Private logo and packaging

- Custom Lock 7 profile molds

- Marketing photo & video support

Suitable for distributors who want to build their own product line.

6.5 Large Production Capacity Ensures Stable Supply

We support:

- 20–30 HQ containers monthly

- Long-term distribution partnerships

- Inventory replenishment

- Special support for hotel or villa projects

6.6 Export Support & Professional Service

We provide:

- Free samples

- Full technical drawings

- Installation manuals

- Certificates (SGS / CE / ISO)

- 24/7 English sales team

- Logistics & shipping assistance

This makes importing from China easier than ever.

Conclusion

The Composite Cladding Lock 7 System is one of the most advanced exterior cladding installation technologies in the global market today. With its seven-point interlocking design, superior waterproofing, strong mechanical stability, and low-maintenance features, it has become the preferred cladding solution for modern residential projects, hotel developments, commercial buildings, industrial facilities, and renovation works.

If you want to import Lock 7 composite cladding from a professional Chinese manufacturer — whether for wholesale, brand distribution, or large construction projects — we can support you with factory pricing, OEM customization, and stable global supply.