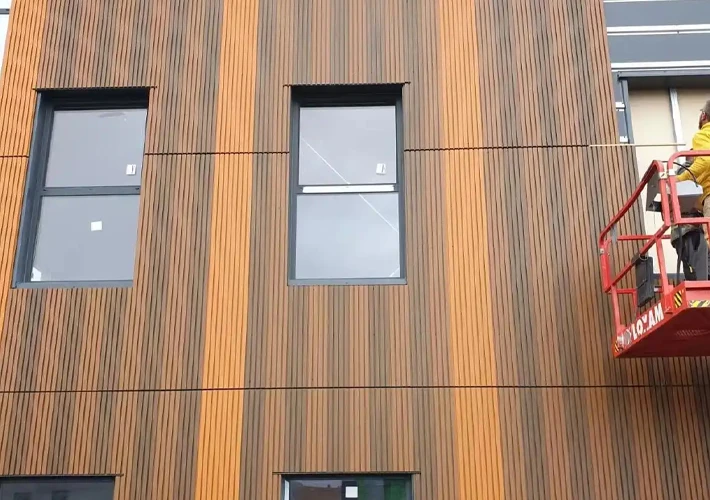

Composite cladding systems have evolved rapidly in recent years, especially for commercial buildings, hotels, modular construction, and large-scale façade projects. Among these systems, composite cladding Lock-7 has become a frequently searched and discussed term in the international building materials market. However, many buyers, architects, and contractors still have only a vague understanding of what Lock-7 actually means, how it works, and why it matters when choosing composite wall cladding.

This in-depth article will comprehensively explain what composite cladding Lock-7 is, how it differs from other locking systems, its structural principles, advantages, applications, installation considerations, and why Lock-7 has become a preferred choice for modern façade and interior wall projects—especially in B2B sourcing from professional manufacturers.

Table of Contents

ToggleUnderstanding Composite Cladding Systems

Before explaining Lock-7 specifically, it is important to understand what composite cladding refers to in the construction and decoration industry.

Composite cladding generally means wall or façade panels made from multiple engineered materials, such as:

- WPC (Wood Plastic Composite)

- Aluminum composite + core materials

- Fiber cement composite panels

- Polymer-based decorative cladding

- High-density composite boards with surface films

These materials are designed to combine the strength, durability, and weather resistance of industrial materials with the aesthetic appearance of wood, stone, metal, or concrete.

Composite cladding is widely used for:

- Exterior façades

- Interior feature walls

- Commercial buildings

- Hotels and resorts

- Office buildings

- Retail spaces

- Modular and prefabricated buildings

As composite cladding adoption increased, installation efficiency and structural stability became critical factors—this is where locking systems like Lock-7 emerged.

What Does “Lock-7” Mean in Composite Cladding?

Composite cladding Lock-7 refers to a specific interlocking panel connection structure, usually involving seven structural locking points or layers within the panel profile design.

Rather than being a brand name, Lock-7 is a structural concept commonly used by manufacturers to describe an advanced tongue-and-groove or click-lock system with enhanced mechanical performance.

In simple terms, Lock-7 means:

- The panel edges are engineered with multiple interlocking contact points

- These points create stronger panel engagement

- The system improves load distribution, wind resistance, and installation stability

Lock-7 systems are most commonly found in:

- WPC composite cladding

- Exterior wall composite panels

- Fire-rated composite cladding

- High-density architectural cladding boards

Structural Design Principle of Composite Cladding Lock-7

The core value of Lock-7 lies in its profile engineering.

1.Multi-Layer Interlocking Geometry

A traditional cladding panel may have:

- 1–2 simple tongue-and-groove points

A Lock-7 panel typically features:

Seven mechanical engagement zones, which may include:

- Primary tongue

- Secondary locking ribs

- Anti-slip grooves

- Expansion control gaps

- Stress-relief cavities

- Water-drainage channels

- Back-locking support lips

These layers work together to create a self-reinforcing structure.

2.Load Distribution and Stress Control

Lock-7 designs allow external forces—such as:

- Wind pressure

- Thermal expansion

- Structural vibration

to be distributed across multiple locking points, instead of being concentrated on screws or clips alone.

This significantly reduces:

- Panel deformation

- Edge cracking

- Long-term loosening

3.Concealed Fixing Compatibility

Most Lock-7 composite cladding systems are compatible with:

- Hidden fasteners

- Concealed clips

- Back-locking brackets

This improves:

- Visual cleanliness

- Corrosion resistance

- Long-term façade integrity

Key Advantages of Composite Cladding Lock-7

1.Superior Structural Stability

Compared with basic tongue-and-groove panels, Lock-7 systems offer:

- Stronger panel-to-panel bonding

- Reduced risk of panel separation

- Better resistance to wind uplift

This is especially important for:

- High-rise buildings

- Coastal projects

- Regions with strong wind loads

2.Faster and Safer Installation

Lock-7 composite cladding panels are designed for:

- Precise alignment

- Reduced installation errors

- Lower labor dependency

Benefits include:

- Shorter construction cycles

- Lower labor costs

- More consistent installation quality

For large commercial projects, this efficiency translates directly into cost savings.

3.Improved Waterproof Performance

The multi-lock structure typically integrates:

- Overlapping joints

- Drainage channels

- Capillary break zones

This minimizes:

- Rainwater penetration

- Moisture accumulation

- Long-term substrate damage

As a result, Lock-7 cladding performs better in humid, rainy, or coastal environments.

4.Enhanced Thermal Expansion Control

Composite materials naturally expand and contract with temperature changes.

Lock-7 systems are engineered to:

- Allow controlled micro-movement

- Prevent panel warping

- Avoid surface buckling

This is critical for:

- Exterior façades

- Dark-color cladding exposed to sunlight

- Large continuous wall surfaces

5.Cleaner Aesthetic Appearance

Because Lock-7 systems often support hidden fastening, they offer:

- No visible screws

- Smooth panel transitions

- High-end architectural finishes

This makes Lock-7 composite cladding ideal for:

- Hotels

- Office lobbies

- Luxury residential projects

- Commercial façades

Composite Cladding Lock-7 vs Traditional Locking Systems

| Feature | Traditional T&G | Click-Lock | Lock-7 Composite |

|---|---|---|---|

| Locking points | 1–2 | 2–3 | 7 integrated |

| Structural strength | Medium | Medium-High | High |

| Wind resistance | Limited | Good | Excellent |

| Waterproofing | Basic | Improved | Advanced |

| Installation speed | Medium | Fast | Very fast |

| Long-term stability | Moderate | Good | Excellent |

This comparison explains why Lock-7 has become increasingly popular in professional construction projects.

Applications of Composite Cladding Lock-7

1.Exterior Wall Cladding

Lock-7 is widely used in:

- Commercial façades

- Industrial buildings

- Residential exterior walls

Its strength and weather resistance make it suitable for long-term outdoor exposure.

2.Hotel and Resort Projects

Hotels demand:

- High aesthetics

- Quiet interiors

- Durable materials

Lock-7 composite cladding delivers:

- Seamless finishes

- Stable installation

- Reduced maintenance over time

3.Modular and Prefabricated Buildings

In modular construction:

- Speed and precision are critical

Lock-7 systems allow:

- Factory-preinstalled panels

- Quick on-site assembly

- Consistent quality control

4.Interior Feature Walls

Although designed for structural performance, Lock-7 is also used indoors for:

- Accent walls

- Commercial interiors

- Retail displays

The concealed locking enhances visual appeal.

Materials Commonly Used in Lock-7 Composite Cladding

Lock-7 is a structural profile, not a material itself. It can be applied to various composite materials, including:

1.WPC (Wood Plastic Composite)

- Wood fiber + polymer resin

- Moisture resistant

- Eco-friendly option

Widely used for:

- Exterior cladding

- Decorative wall panels

2.High-Density Polymer Composite

- Strong impact resistance

- Lightweight

- Uniform quality

Common in:

- Commercial façades

- Interior wall systems

3.Fire-Rated Composite Panels

- Mineral-filled core

- Enhanced fire performance

- Meets international fire standards

Often used in:

- Public buildings

- High-rise projects

Installation System and Substructure Requirements

To maximize the performance of Lock-7 composite cladding, correct installation is essential.

Substructure Options

- Galvanized steel framework

- Aluminum battens

- Treated wooden battens (interior use)

Fixing Methods

- Concealed stainless steel clips

- Back-locking screws

- Expansion-controlled fasteners

Professional manufacturers usually provide complete installation drawings and technical manuals.

Quality Standards and Performance Testing

High-quality Lock-7 composite cladding should pass tests such as:

- Wind load resistance

- Thermal cycling

- Water penetration testing

- UV aging resistance

- Impact resistance

For international projects, compliance with standards such as:

- ISO

- ASTM

- EN

- CE

is often required.

Why Lock-7 Composite Cladding Is Popular in Global B2B Markets

International buyers increasingly prefer Lock-7 systems because they offer:

- Reduced installation risks

- Predictable performance

- Long service life

- Lower lifecycle costs

From a B2B perspective, Lock-7 composite cladding is especially attractive for:

- Distributors

- Wholesalers

- Project contractors

- Developers

Many professional Chinese composite cladding factories now specialize in Lock-7 profile development, offering:

- Custom profiles

- OEM/ODM services

- Large-scale production

- Stable export quality

Common Questions About Composite Cladding Lock-7

Is Lock-7 a patented system?

Lock-7 usually refers to a design concept, not a single patented product. Specific profiles may be patented by individual manufacturers.

Is Lock-7 suitable for exterior use?

Yes. Lock-7 is specifically designed to improve exterior wall performance.

Does Lock-7 increase material cost?

The panel profile may be slightly more complex, but overall project costs often decrease due to faster installation and fewer failures.

Conclusion

Composite cladding Lock-7 is not just a marketing term—it represents an advanced interlocking structural design that significantly improves the performance, safety, and installation efficiency of modern composite cladding systems.

By offering:

- Multi-point mechanical locking

- Superior structural stability

- Enhanced waterproofing

- Cleaner visual appearance

Lock-7 composite cladding has become a preferred solution for commercial, residential, and industrial projects worldwide.

For B2B buyers, sourcing Lock-7 composite cladding from experienced manufacturers—especially those with mature production technology and international export experience—can deliver long-term value, reduced risk, and consistent project quality.

If you are evaluating composite cladding solutions for your next project, understanding Lock-7 is an essential step toward making a professional, future-proof material decision.