Composite cladding has become one of the most popular exterior and interior wall solutions in modern construction and renovation projects. From residential homes and commercial buildings to hotels, resorts, and public facilities, composite cladding is widely used for its durability, aesthetics, and low maintenance requirements.

In this in-depth guide, we will explain what composite cladding is, how it is made, its main types, advantages and disadvantages, applications, installation methods, quality standards, and global market trends. This article is written for architects, developers, contractors, and B2B buyers looking for a professional and practical understanding of composite cladding products.

Table of Contents

ToggleDefinition of Composite Cladding

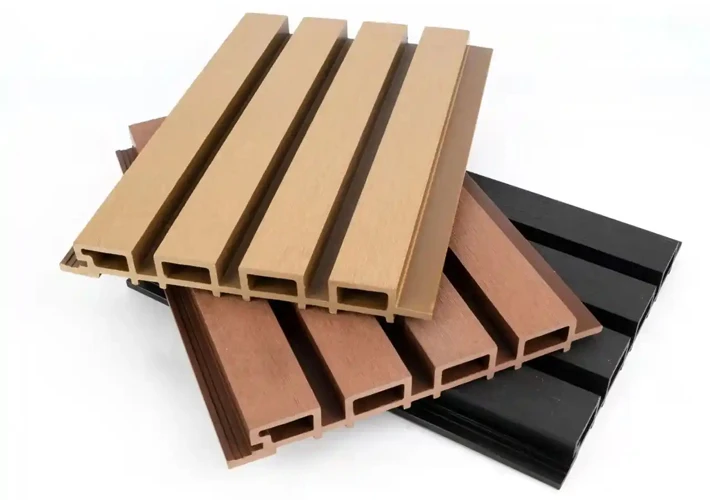

Composite cladding is a building material made by combining two or more different materials to create a cladding board with enhanced performance compared to traditional single-material products. The most common form of composite cladding is Wood Plastic Composite (WPC) cladding, which blends wood fibers with thermoplastics and additives.

Unlike natural wood cladding, composite cladding is engineered to resist moisture, insects, UV radiation, and weathering. Unlike metal or cement-based cladding, it offers a warm, natural wood-like appearance while remaining lightweight and easy to install.

In simple terms, composite cladding is designed to:

- Protect building structures

- Improve thermal and acoustic performance

- Enhance architectural appearance

- Reduce long-term maintenance costs

What Is Composite Cladding Made Of?

The composition of composite cladding varies depending on the product type and manufacturing process, but most composite cladding panels consist of the following components:

2.1 Wood Fibers or Natural Fillers

These are usually:

- Wood powder

- Bamboo fiber

- Rice husk fiber

They provide the natural texture and appearance of wood and improve stiffness.

2.2 Plastic Polymers

Common plastics used include:

- HDPE (High-Density Polyethylene)

- PVC (Polyvinyl Chloride)

- PP (Polypropylene)

The plastic component improves water resistance, durability, and flexibility.

2.3 Additives

Additives are essential for performance enhancement, such as:

- UV stabilizers (prevent fading)

- Anti-oxidants (extend lifespan)

- Coupling agents (improve bonding)

- Color pigments

- Fire retardants (for higher fire ratings)

2.4 Optional Co-Extrusion Layer

High-end composite cladding often features a co-extruded protective layer, which significantly improves:

- Scratch resistance

- Color stability

- Stain resistance

- Moisture resistance

Main Types of Composite Cladding

Composite cladding can be categorized based on structure, material, and application.

3.1 WPC Composite Cladding

The most common type, suitable for:

- Exterior façades

- Garden walls

- Balcony and terrace walls

It combines wood fibers and plastic through extrusion molding.

3.2 Co-Extrusion Composite Cladding

This is an upgraded version of traditional WPC cladding, featuring:

- A solid core

- A protective outer shell

It offers superior durability and is ideal for harsh climates.

3.3 Hollow vs Solid Composite Cladding

- Hollow composite cladding: Lightweight, cost-effective, suitable for large-area projects.

- Solid composite cladding: Higher strength, better impact resistance, preferred for premium projects.

3.4 Interior Composite Wall Cladding

Used indoors for:

- Feature walls

- Commercial interiors

- Hotel lobbies

It focuses more on appearance than weather resistance.

Key Advantages of Composite Cladding

Composite cladding has gained global popularity due to its balanced performance and cost-efficiency.

4.1 High Durability

Composite cladding resists:

- Rot and decay

- Termites and insects

- Cracking and warping

With proper installation, it can last 20–30 years or more.

4.2 Excellent Weather Resistance

It performs well in:

- Humid coastal areas

- Hot and sunny regions

- Cold climates with temperature fluctuations

4.3 Low Maintenance

Unlike natural wood, composite cladding does not require:

- Regular painting

- Oiling or sealing

Simple cleaning with water is usually sufficient.

4.4 Consistent Appearance

Factory-controlled production ensures:

- Uniform color

- Consistent texture

- Stable dimensions

This is especially important for large-scale projects.

4.5 Eco-Friendly and Sustainable

Many composite cladding products use:

- Recycled plastics

- Renewable wood fibers

This reduces deforestation and plastic waste.

4.6 Design Versatility

Composite cladding is available in:

- Wood grain finishes

- Modern flat designs

- Multiple colors and profiles

It suits both traditional and contemporary architecture.

Disadvantages of Composite Cladding

While composite cladding has many benefits, it is important to understand its limitations.

5.1 Higher Initial Cost Than Some Traditional Materials

Compared with basic PVC panels or untreated wood, composite cladding may have a higher upfront cost. However, this is often offset by lower maintenance expenses over time.

5.2 Thermal Expansion

Composite materials expand and contract with temperature changes. Proper installation gaps and accessories are essential to avoid deformation.

5.3 Weight Compared to PVC Panels

Composite cladding is heavier than pure PVC products, requiring proper sub-structure support.

Applications of Composite Cladding

Composite cladding is suitable for a wide range of applications across different industries.

6.1 Residential Buildings

- Exterior house façades

- Garden walls

- Garage walls

- Balcony enclosures

6.2 Commercial and Public Buildings

- Office buildings

- Shopping malls

- Schools and hospitals

- Transportation hubs

6.3 Hospitality Industry

- Hotel exterior walls

- Resort villas

- Outdoor decorative walls

Composite cladding is especially popular in hotels due to its durability and premium appearance.

6.4 Renovation Projects

Its lightweight nature makes composite cladding ideal for:

- Old building renovation

- Façade upgrades

- Energy-efficiency improvements

Composite Cladding Installation Methods

Correct installation is critical for performance and longevity.

7.1 Substructure Preparation

Common substructures include:

- Aluminum profiles

- Galvanized steel frames

- Treated wooden battens

The structure must be level, strong, and well-ventilated.

7.2 Fixing Methods

- Hidden clips (preferred for aesthetics)

- Stainless steel screws (visible or concealed)

7.3 Expansion Gaps

Expansion gaps must be reserved:

- Between boards

- At wall edges

- Around corners and joints

7.4 Ventilation Design

Proper airflow behind the cladding prevents:

- Moisture buildup

- Mold growth

- Heat accumulation

Composite Cladding vs Traditional Cladding Materials

8.1 Composite Cladding vs Natural Wood

| Aspect | Composite Cladding | Natural Wood |

|---|---|---|

| Maintenance | Low | High |

| Lifespan | Long | Medium |

| Weather Resistance | Excellent | Limited |

| Cost Over Time | Lower | Higher |

8.2 Composite Cladding vs Metal Cladding

Composite cladding offers better:

- Thermal comfort

- Sound insulation

- Aesthetic warmth

Metal cladding, however, excels in industrial designs.

8.3 Composite Cladding vs Fiber Cement

Composite cladding is:

- Lighter

- Easier to install

- More flexible in design

Fiber cement has higher fire resistance but is more brittle.

Quality Standards and Testing for Composite Cladding

For global buyers, understanding quality standards is essential.

9.1 Common Performance Tests

- UV resistance testing

- Water absorption testing

- Impact resistance

- Slip resistance (for specific profiles)

9.2 International Standards

High-quality composite cladding manufacturers typically comply with:

- ISO quality management systems

- Fire rating standards

- Environmental protection regulations

9.3 Factory Quality Control

Reliable manufacturers implement:

- Raw material inspection

- In-process quality checks

- Finished product testing

- Batch traceability

Packaging and Export of Composite Cladding

For international trade, packaging and logistics are crucial.

10.1 Packaging Methods

Composite cladding is usually packed using:

- Protective film

- Foam sheets

- Strong cartons or pallets

10.2 Container Loading

Efficient container loading helps:

- Reduce transportation costs

- Prevent damage

- Improve delivery efficiency

10.3 Export Documentation

Professional exporters provide:

- Commercial invoices

- Packing lists

- Certificates of origin

- Test reports if required

Global Market Trends for Composite Cladding

11.1 Growing Demand for Sustainable Materials

Green building concepts are driving demand for eco-friendly composite cladding worldwide.

11.2 Popular Markets

Major markets include:

- Europe

- North America

- Australia

- Middle East

- Southeast Asia

11.3 Design Trends

- Natural wood tones

- Dark modern colors

- Wide-panel profiles

- Seamless façade systems

How to Choose the Right Composite Cladding Supplier

For B2B buyers, selecting the right supplier is as important as choosing the product.

12.1 Manufacturing Experience

Choose factories with:

- Long-term production experience

- Stable raw material supply

- Advanced extrusion lines

12.2 Customization Ability

Professional suppliers offer:

- Size customization

- Color matching

- Surface texture options

- OEM and private labeling

12.3 Technical Support

Good suppliers provide:

- Installation guidance

- Sample testing

- Project solutions

Is Composite Cladding Worth It?

From a long-term perspective, composite cladding offers excellent value. Although the initial investment may be slightly higher than basic materials, its durability, low maintenance, and consistent appearance make it a cost-effective solution for modern construction projects.

For developers, architects, and global buyers, composite cladding balances performance, aesthetics, sustainability, and cost control, making it one of the most practical façade solutions available today.

Conclusion

So, what is a composite cladding?

Composite cladding is an advanced building material engineered by combining wood fibers, plastics, and additives to create a durable, low-maintenance, and visually appealing wall cladding solution. It is widely used in residential, commercial, and hospitality projects worldwide and continues to grow in popularity due to sustainability and design flexibility.

As construction standards rise and long-term performance becomes more important, composite cladding is no longer just an alternative—it is becoming a mainstream choice in modern architecture.

If you are planning a new project or sourcing cladding materials for international markets, understanding composite cladding in depth will help you make smarter, more profitable decisions.