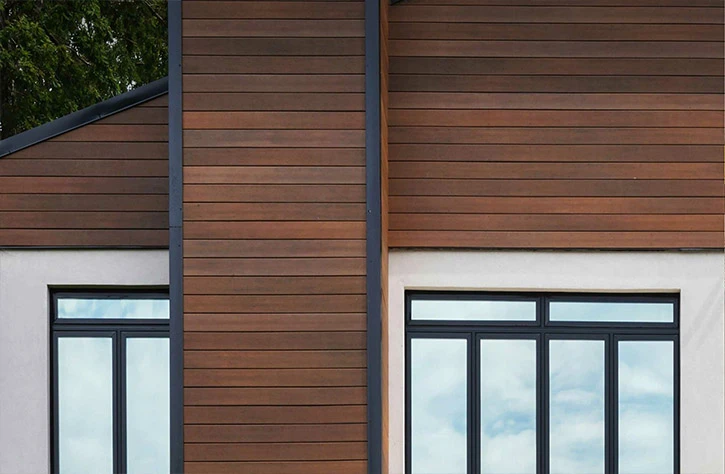

Composite wood cladding offers a smarter alternative—delivering the aesthetic appeal of real wood while slashing maintenance costs by 50% or more over the building’s lifespan. In this article, we’ll explore why developers are increasingly choosing composite solutions, how they achieve such dramatic savings, and what factors to consider when specifying materials for your next project.

Table of Contents

ToggleWhy Maintenance Costs Matter in Development

For developers, maintenance isn’t just an operational concern—it impacts:

- Resale and rental value (poor upkeep reduces property attractiveness)

- Warranty claims (premature material failure leads to disputes)

- HOA and tenant satisfaction (peeling or warping cladding triggers complaints)

A cladding system that requires minimal upkeep directly improves profit margins and asset longevity.

How Composite Wood Cladding Reduces Maintenance by 50 %+

1. No Staining, Sealing, or Repainting

Unlike natural wood, composite wood cladding:

- Retains color without coatings (UV-resistant pigments prevent fading)

- Never requires sanding or resealing (no surface degradation)

- Eliminates paint peeling issues (consistent appearance for decades)

Savings: Developers avoid recurring refinishing costs every 3–5 years.

2. Resists Rot, Mold, and Insect Damage

Composite materials blend wood fibers with polymers, making them:

- Impervious to moisture absorption (no swelling or decay)

- Unattractive to termites and wood-boring insects (no chemical treatments needed)

- Mold-resistant (ideal for humid climates)

Savings: Zero rot repair or pest control expenses over 20+ years.

3. Withstands Extreme Weather Without Warping

Engineered for durability, composite wood cladding:

- Stays dimensionally stable in freeze-thaw cycles (no cracking)

- Resists high winds (unlike brittle vinyl, which can detach)

- Performs in coastal areas (salt spray won’t degrade it)

Savings: No post-storm cladding replacements or insurance claims.

4. Easy Cleaning = Lower Operational Costs

Maintenance is limited to:

- Occasional rinsing with water (no pressure washing required)

- Mild soap for stubborn stains (no abrasive scrubbing)

Savings: Cut facade cleaning budgets by 75% vs. painted wood.

Case Study: Composite vs. Timber Cladding Over 15 Years

| Cost Factor | Natural Timber Cladding | Composite Wood Cladding |

| Initial Material | Lower | Higher (+15–25%) |

| Installation | Similar | Similar |

| Refinishing | Every 3–5 years | Never |

| Repairs | Rot/insect damage | None |

| Cleaning | Annual deep cleaning | Biannual rinsing |

| Total 15-Year Cost | High (+100%+) | Low (50% savings) |

Additional Developer Benefits

1. Faster Project Turnarounds

- Pre-finished panels eliminate onsite staining delays.

- Lightweight = quicker installation vs. brick or stone.

2. Higher Property Valuations

- Curb appeal lasts decades, attracting premium buyers/tenants.

- Sustainability credentials (many composites use recycled content).

3. Compliance & Warranty Advantages

- Class A fire-rated options are available for multi-family builds.

- 25–30-year warranties (vs. 10–15 years for treated wood).

Choosing the Right Composite Wood Cladding

To maximize savings, developers should evaluate:

✔ Material composition (WPC vs. mineral-core composites)

✔ Fire ratings (critical for multi-story buildings)

✔ Profile options (ship-lap, batten, or hidden fastener systems)

✔ Supplier track record (warranty support matters)

Conclusion

Composite wood cladding isn’t just an alternative to timber—it’s a strategic cost-saving tool. By cutting maintenance budgets by 50% or more it boosts ROI, asset value, and tenant satisfaction while minimizing operational headaches. Get Free Samples for Your Next Development